Loading... Please wait...

Loading... Please wait...- Home

- Cryogenic Storage & Handling

- LN2 Transfer & Dispensing

- Insulon Vacuum Jacketed Low Pressure Hose

Insulon Vacuum Jacketed Low Pressure Hose

Price:

$259.97

SKU:

11057A

Weight:

5.00 LBS

Availability:

1-3 Weeks

Shipping:

Calculated at checkout

Product Description

The Insulon® Low Pressure Insulated Hoses are vacuum jacketed hoses for gas or liquid transfer. These hoses utilize a proprietary insulation technology suitable for both cryogenic and high temperatures.

Applications

- Aerospace,

- Automotive,

- Cable & Wire Harnesses,

- Chemical Processing,

- Cleanroom Manufacturing,

- Cryogenic Fluid Transfer,

- Cryotherapy Devices,

- Food-Grade Applications,

- Fuel & Oil Lines.

Features

- Cleanroom-compatible materials (316L stainless steel),

- Compatible with cryogenic fluids including hydrogen, LN2, many others,

- Durable, reliable construction,

- Easy to install, clean and sterilize,

- Improve thermal energy efficiency,

- Low spring back reduces stress on connections and joints,

- Maintain safer external surface temperature,

- Minimize heat loss and conserve thermal energy,

- Naturally flame-retardant materials,

- Non-fibrous materials,

- Reduce condensation, dripping, and risk of mold,

- Reduce cryogenic material losses due to boil-off,

- Reduce risk of corrosion-under-insulation (CUI).

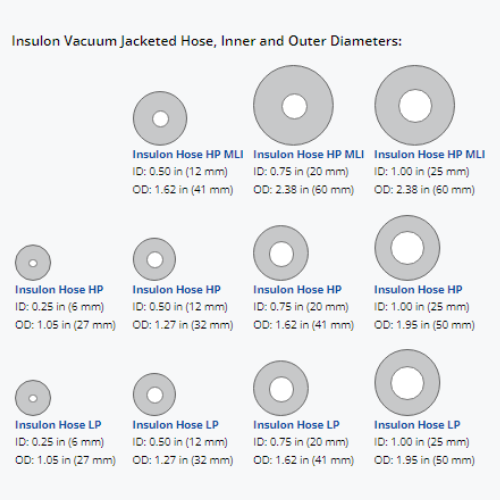

Specifications

- Thermal Range: -270°C to 900°C (-454°F to 1652°F),

- Jacket material: 316L Stainless Steel,

| Inner Diameter (in) | 1/4 | 1/2 | 3/4 | 1 |

| Outer Diameter (in) | 1.5 | 1.27 | 1.62 | 1.95 |

| Bend Radius Static (in.) | 2.65 | 3.33 | 4.1 | 5.08 |

| Bend Radius Dynamic (in.) | 6.58 | 7.5 | 10.2 | 11.75 |

| Maximum Allowable Working Pressure (MAWP) | 72 | 43 | ||

- Tube Stub

-

- Stainless steel

| ID (in) | 1/4 | 1/2 | 3/4 | 1 |

| Tube Stub OD (in) | 0.250 | .500 | .750 | 1.00 |

| Tube Stub Thickness (in) | 0.035 | 0.049 | ||

| Min. Tube Stub ID (in) | 0.180 | 0.430 | 0.680 |

0.902 |

- Pressure tests are conducted at 1.5x MAWP according to NAHAD Corrugated Metal Hose Assembly Specification Guidelines, p. 33 (2005).

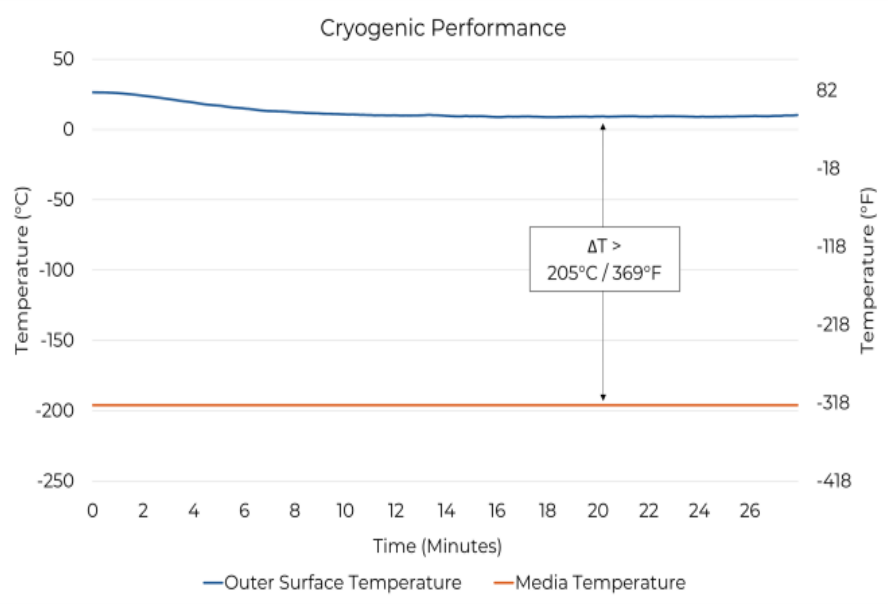

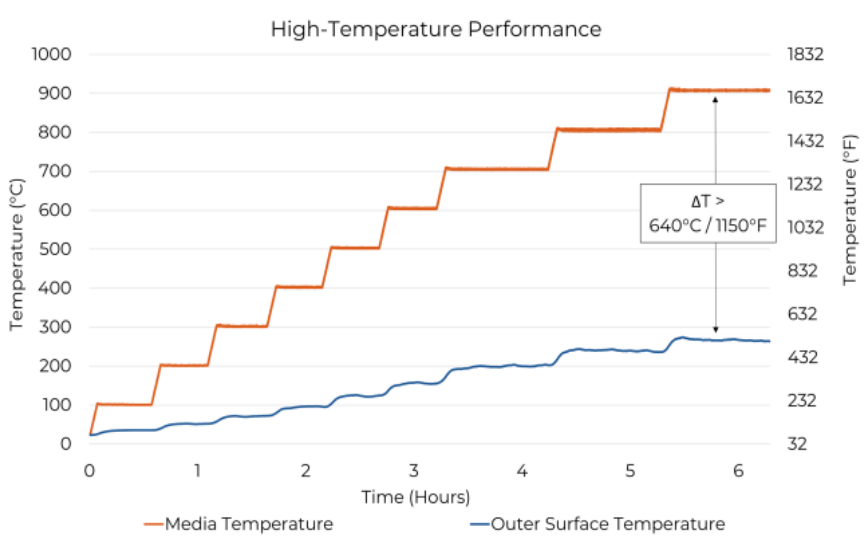

- Insulation “touch temperature” performance for 6ft Length Hose:

- Cryogenic Performance: For LN2 (at -196°C) the hose jacket temperature was over 9°C, for temperature difference (∆T) of >205°C (369°F) warmer.

- High Temperature Performance: For hot air (at 900°C (1652°F) the hose jacket temperature maintained under 260°C (482°F), for temperature difference (∆T) of >205°C (369°F) cooler.

- This chart illustrates the difference between the media temperature (hot air) and the outer surface temperature (aka “touch temperature”). When the process media was 900°C (1652°F), the temperature difference was over 640°C (1150°F) at steady state.

- Insulation Reliability with Thermal Cycling:

- >20,000 cycles at 450°C without drop in insulation performance.

- Cycle was defined as a 3-minute ramp up during which the component reaches steady-state, followed by a 2-minute cool-down period. Ambient temperature was 23°C.

Optional Accessories

- End Fittings:

- Compression Union

- Brass by default unless Stainless Steel is requested.

- Compatible with all hose diameter options.

- Compression Male NPT

- Brass by default unless Stainless Steel is requested.

- Compatible with all hose diameter options.

- JIC 37 Degrees

- Compatible with all hose diameter options.

- CGA-295

- Compatible with

- Compatible with 1/2" hose diameter option only.

- Phase Separator

- Brass

- Compatible with 1/2" hose diameter option only.

- Contact LabGearUSA for customized hose requests:

- Custom hose Lengths are available 2ft - 65ft.

- Custom configurations may have longer lead times.

---

Warranty Information

Manufacturer's Warranty:

The manufacturer warrants its products to be free of detects in materials and workmanship for the stated period from date of original purchase invoice. All warranties or merchant ability and fitness for any purpose and all other warranties, expressed or implied, except those expressly set forth herein, are deemed waived and excluded. Manufacturer's duty under the warranty is limited to replacement and/or repair of the defective part at their exclusive option. Seller shall not be liable for any expenses or damages incurred by the purchaser except as expressly set forth herein, and in no event shall seller or manufacturer be liable for any special, incidental or consequential damages of any kind. This warranty does not supersede any statutory rights that may be available in certain countries. The foregoing manufacturer's warranty of shall be voided, and of no force and effect if buyer has modified or damaged the product.

The manufacturer warrants its products to be free of detects in materials and workmanship for the stated period from date of original purchase invoice. All warranties or merchant ability and fitness for any purpose and all other warranties, expressed or implied, except those expressly set forth herein, are deemed waived and excluded. Manufacturer's duty under the warranty is limited to replacement and/or repair of the defective part at their exclusive option. Seller shall not be liable for any expenses or damages incurred by the purchaser except as expressly set forth herein, and in no event shall seller or manufacturer be liable for any special, incidental or consequential damages of any kind. This warranty does not supersede any statutory rights that may be available in certain countries. The foregoing manufacturer's warranty of shall be voided, and of no force and effect if buyer has modified or damaged the product.

Find Similar Products by Category

Currency Converter

Choose a currency below to display product prices in the selected currency.

-

Default Currency

Default Currency

-

EURO

EURO

-

ARA - ARGENTINA

ARA - ARGENTINA

-

AUD - AUSTRALIA

AUD - AUSTRALIA

-

BRL - BRAZIL

BRL - BRAZIL

-

CAD - CANADA

CAD - CANADA

-

CHF - SWITZERLAND

CHF - SWITZERLAND

-

CLP - CHILE

CLP - CHILE

-

CNY - CHINA

CNY - CHINA

-

CZK - CZECH REPUBLIC

CZK - CZECH REPUBLIC

-

DKK - DENMARK

DKK - DENMARK

-

GBP - GREAT BRITAIN

GBP - GREAT BRITAIN

-

IDR - INDONESIA

IDR - INDONESIA

-

ILS - ISRAEL

ILS - ISRAEL

-

INR - INDIA

INR - INDIA

-

JPY -JAPAN

JPY -JAPAN

-

KRW - SOUTH KOREAN REPUBLIC

KRW - SOUTH KOREAN REPUBLIC

-

MXN - MEXICO

MXN - MEXICO

-

MYR - MALAYSIA

MYR - MALAYSIA

-

NOK - NORWAY

NOK - NORWAY

-

NZD - NEW ZEALAND

NZD - NEW ZEALAND

-

PAB - PANAMA

PAB - PANAMA

-

PHP - PHILIPPINES

PHP - PHILIPPINES

-

PKR - Pakistan

PKR - Pakistan

-

PLN - POLAND

PLN - POLAND

-

RUB - RUSSIA

RUB - RUSSIA

-

SAR - SAUDI ARABIA

SAR - SAUDI ARABIA

-

SEK - SWEDEN

SEK - SWEDEN

-

SGD - SINGAPORE

SGD - SINGAPORE

-

THB - THAILAND

THB - THAILAND

-

TRY - TURKEY

TRY - TURKEY

-

TWD - TAIWAN

TWD - TAIWAN

-

UAH - UKRAINE

UAH - UKRAINE

-

ZAR - SOUTH AFRICA

ZAR - SOUTH AFRICA